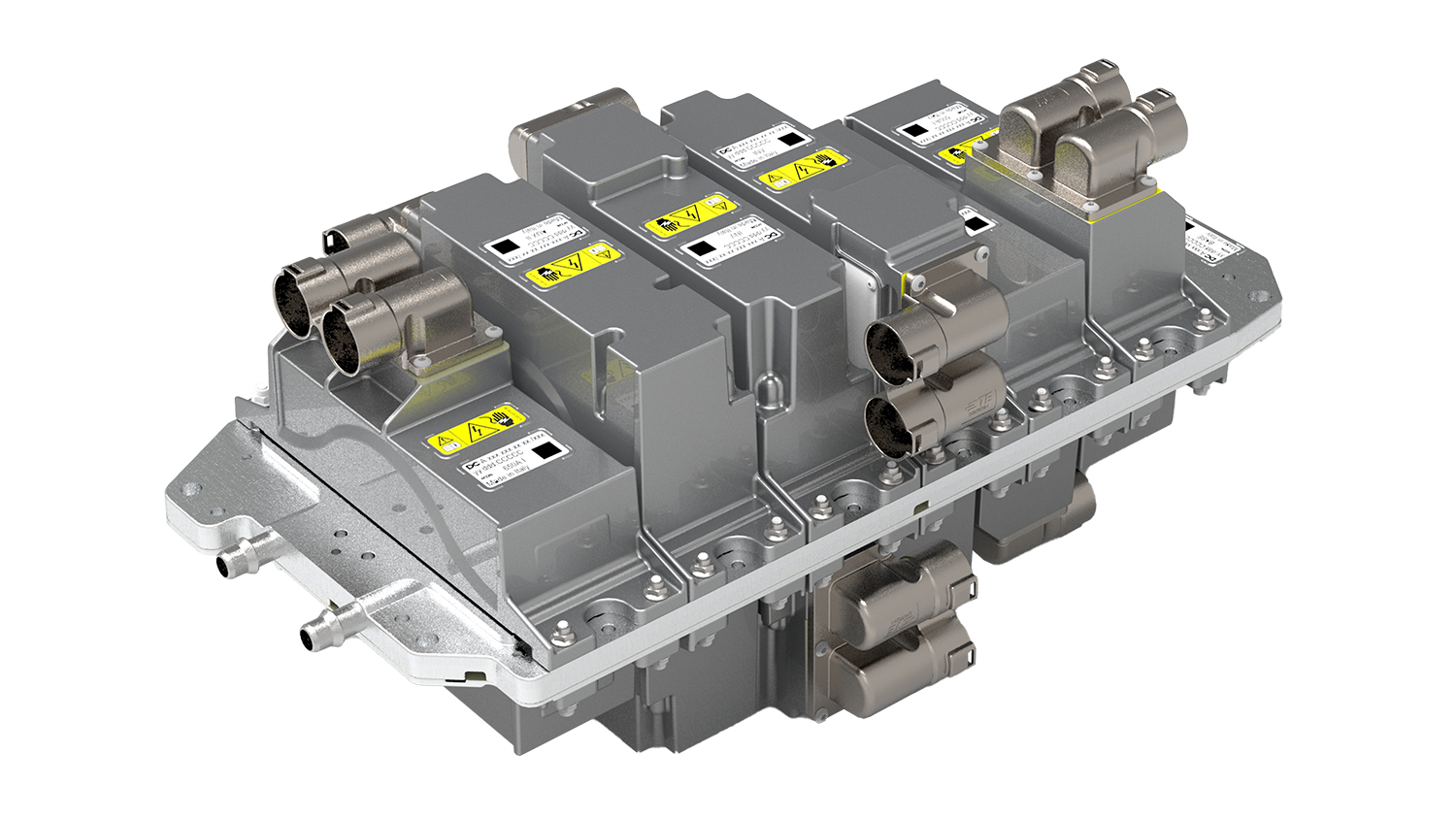

A modular High Voltage unit for heavy duty applications

News – June 2025

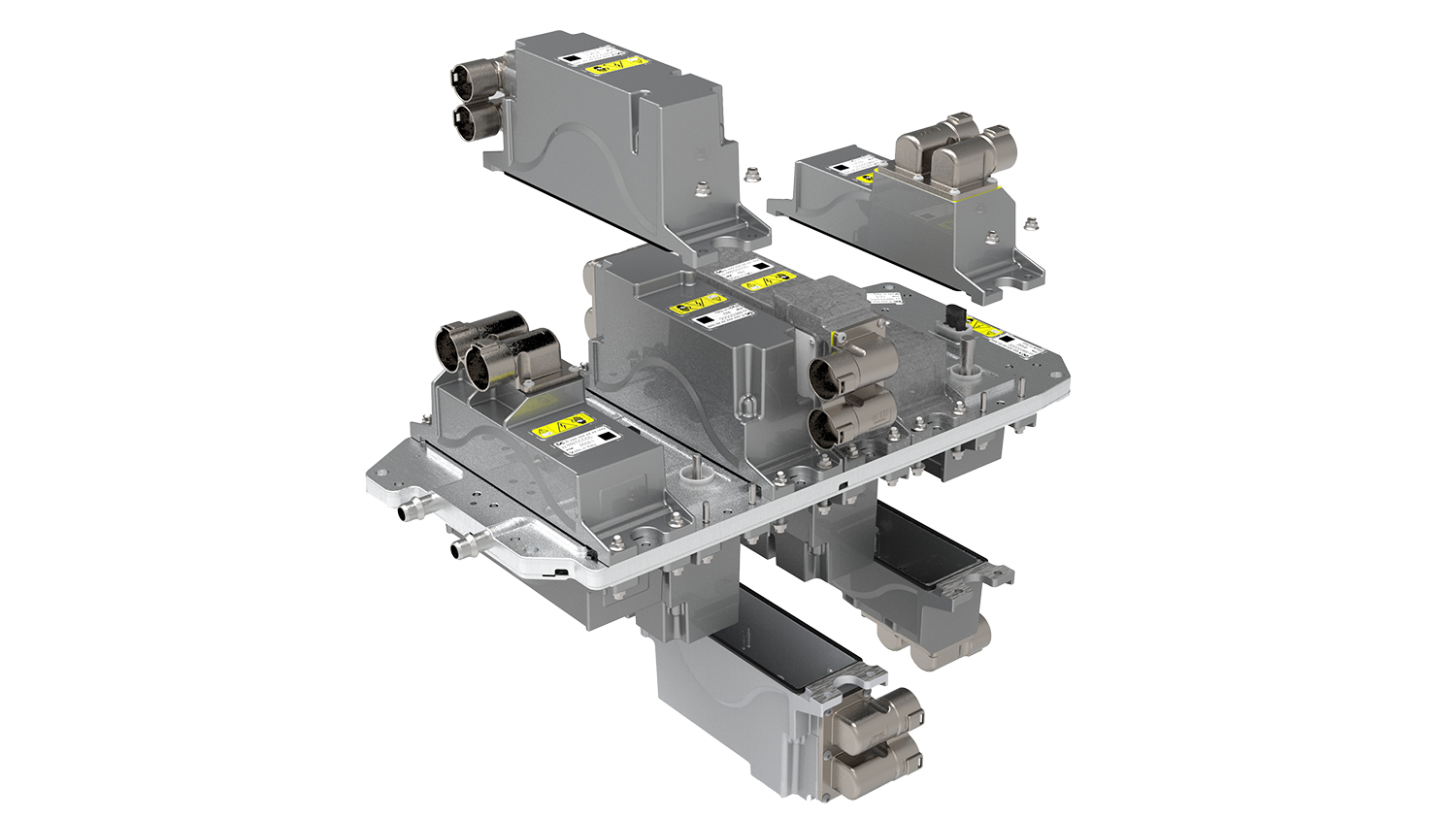

A unit with highly innovative features has recently been developed by our company for a heavy-duty fully electric vehicle. Like with most MTA products, this unit stands out for its modularity. In fact, by adjusting the configuration of its Plug&Play modules, customers can create multiple variants tailored to different vehicle setups.

In addition to these modules, the control unit also features a base plate that houses a liquid cooling system, operates at a maximum voltage of 800 VDC, and receives 900 kW of input power from the batteries, while its output power varies depending on the specific vehicle architecture.

Positioned externally beneath the cab, it is responsible for distributing high-voltage power from the batteries while ensuring the protection and operation of various electrical utilities, such as the ePTO, the cooling fan, and the inverter.

Meticulous attention is paid to the manufacturing of this control unit in order to guarantee both high performance and, most importantly, maximum safety, with IP67 and IP6K69 protection ratings. It is manufactured at our Codogno plant on a dedicated state-of-the-art production line, designed to meet the highest standards of electrical reliability.

The high-voltage connectors integrated into the unit serve a protective function and incorporate HVIL (High Voltage Interlock Loop) technology, which prevents accidents and damage by automatically interrupting high-voltage power flow in hazardous situations.

This modular HV power unit exemplifies the advanced expertise our company has developed in high-voltage management, reinforcing our role as a full-solution provider for power unit manufacturing. It aligns with the most stringent OEM requirements, and is designed for combustion engine vehicles as well as hybrid and fully electric architectures.

Medium and high voltage solutions

MTA designs and manufactures innovative dashboards and displays