Electronic units are assembled with mechanical and optical parts on assembly lines designed by MTA, according to maximum ergonomics principles and supervised by monitoring and error proofing systems that do not allow carrying out the following stages if the previous ones are unsuccessful. The sophisticated functional testing systems have been fully designed by MTA to be suitable for the very advanced functions and the high performance that distinguish its products.

In any case, for the most sophisticated products, a final test is carried out by a human operator to detect the smallest imperfections.

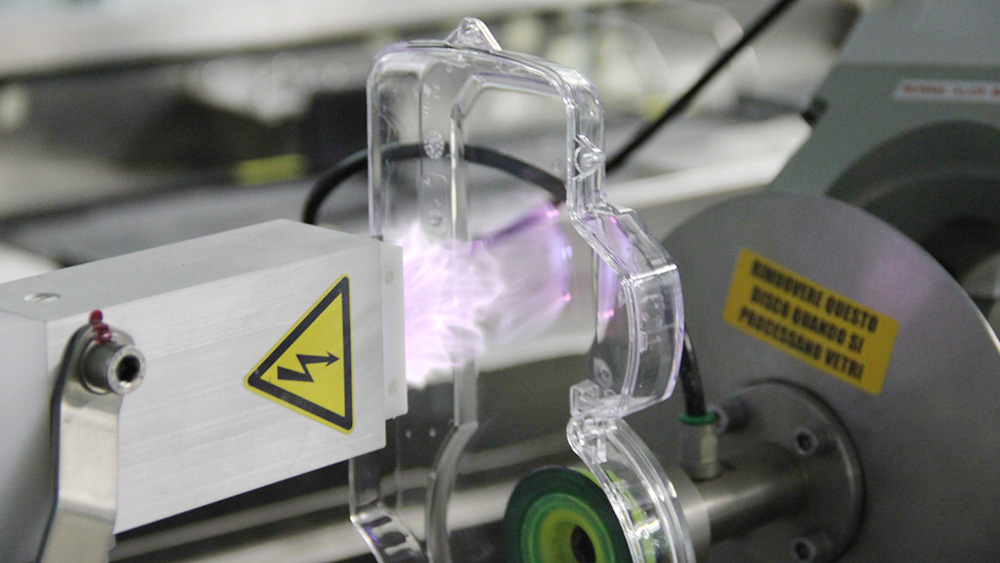

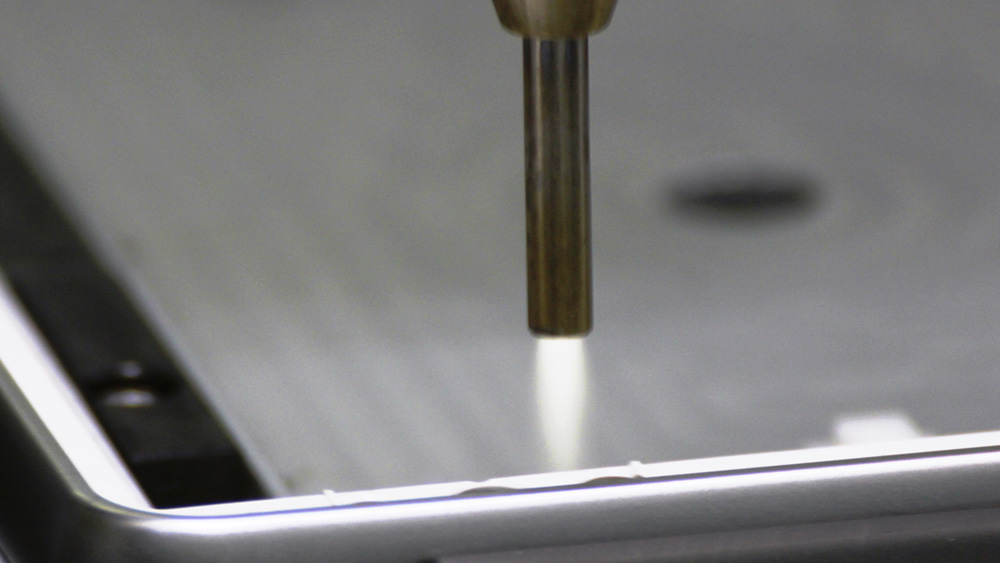

For specific needs, special processes are available: automatic application of Anti Fog film to prevent fogging of Dashboards; glueing of displays to the plastic parts using Hot Melt adhesives with excellent performance; supply of gaskets and sealants for hermetic sealing of products, plasma etching of surfaces and much more.

→ Electronic Assembly and Testing department is in Italy.

The whole electronic manufacturing area in Italy is an Electrostatic Protected Area (EPA), to avoid the presence of electrostatic charges that could cause damage to electronic components, and has a higher atmospheric pressure compared to the outside, ensuring high level of cleanliness. All the lines are provided with sophisticated traceability systems for every single product up to the single component, single test and single event, and the organisational structure allows to meet requests both for large scale and for small series and prototypes.