Our Group has had its own Verification and

Validation Center for many years, where teams of passionate and highly

qualified professionals in testing and validation engineering, specialized in

different areas of expertise, carry out their activities in sophisticated

laboratories. Starting from the setting up of the DV/PV Design Verification

& Product Validation test plan, to diagnosis and problem solving, and then

product certification.

Our laboratories are equipped to simulate,

through consolidated methodologies that follow the guidelines of the reference

standards, any operating condition; each product is subjected to a qualification phase during which numerous tests are carried out:

electromagnetic compatibility tests; electrical tests; mechanical tests, both

static and dynamic; environmental and material tests. These are time-consuming

and thorough procedures that produce excellent results.

The execution of qualification tests takes

place in different locations of the Group in an autonomous way, a necessary

condition to provide customers with the complete know-how from design to

validation, as well as clearly improving the time to market.

In the laboratory in Italy we have a wide

and complete range of environmental conditioning systems such as 4 shaker

vibration systems with climatic chambers, 8 climatic chambers, 3 thermal shock chambers,

2 salt spray chambers, 6 thermostatic chambers, advanced instrumentation for

the execution of electrical and electromagnetic compatibility tests (required

by international directives and specific test specifications of automotive

manufacturers) and a metrology room recently equipped with a new automatic CMM

machine.

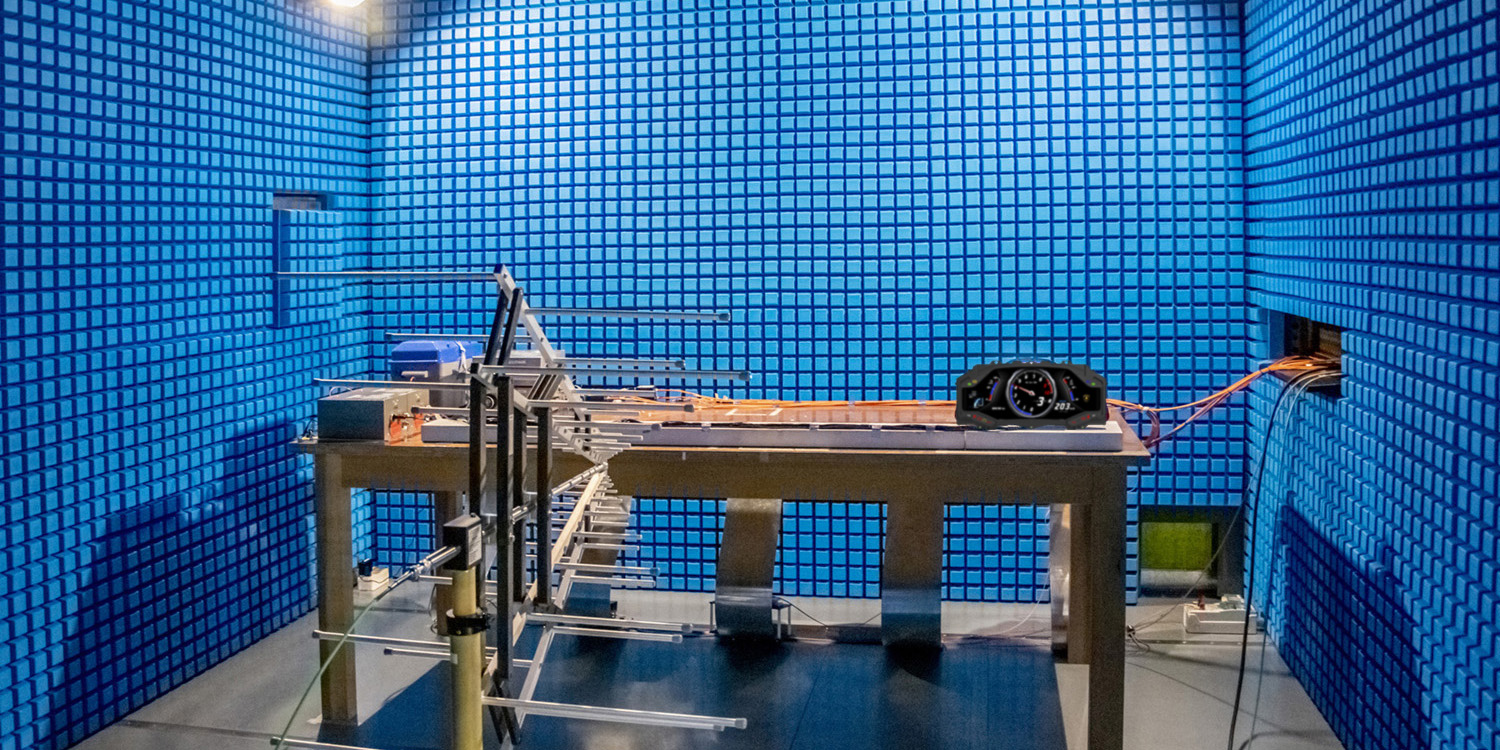

The EMC quality requirements provided for

by the regulations in force and by the specifications of the OEM customers are

achieved with tests carried out in an anechoic chamber and, with the aid of

full compliant instrumentation, tests of radiated and conducted emission

according to CISPR25, tests of immunity to radiated electromagnetic field

according to ISO 11452-2 and conducted with Bulk Current Injection method

according to ISO 11452-4 are carried out.

With the aid of a compact anechoic chamber

and a radio communications tester, products developed by MTA and equipped with

wireless capabilities (Bluetooth and Wi-Fi) are subjected to pre-certification

emission tests and the necessary diagnostic measurements via radio (OTA - Over

The Air).

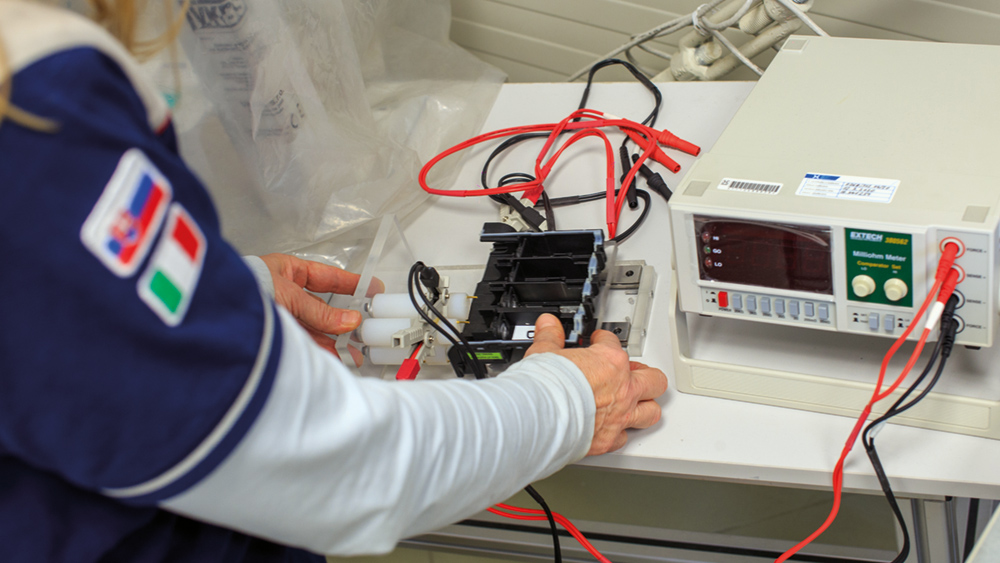

Tests of immunity to electrical transients

on power and signal lines, in accordance with ISO 7637 and customer

specifications, are performed on test benches fully equipped for this purpose.

The impact of ESD electrostatic discharge

on devices is evaluated with immunity tests performed in accordance with ISO

10605 and variants introduced by the specific requirements of automotive

manufacturers.

A specific test environment and a precision

spectroradiometer allow the analysis of the photometric characteristics of

dashboards and displays.

The new lab in MTA Morocco is equipped to

do all electrical, mechanical and environmental testing for the power

distribution units assembled on site and supplied directly to customers.

The instrumentation in Morocco is larger

than that in Codogno to cope with the fact that the PDUs are increasingly

important in size, more powerful, heavier and must be tested in greater numbers

because of the higher levels of reliability required today.

Worth mentioning are the 2 600 l and 1000 l

climatic chambers, a 1200 l salt spray test chamber, a thermal shock chamber, a

600 l chamber for vibrating system, a vibrating system with 22 kN slip table.

In MTA Brasil, the laboratory, which has

been set up for several years now, has been updated during the many

interventions carried out in 2020.

It is equipped with two climatic chambers

from -70°C to +150°C; a 600-liter salt spray test chamber; a 350-liter chamber

for thermal shocks from -70°C to -180°C, as well as numerous electrical and

electronic equipment.

The laboratory in China was set up as soon

as the entire business moved to its current site. Since 2017, in a dedicated

area, the main tests are carried out, such as those on dimensional, electrical,

mechanical, environmental aspects, mainly aimed at quality tests of connectors

and PDUs.

The laboratory is also equipped to cope

with an expected increase in the product range that will be supplied from China

to some important OEMs and that needs the guarantee of all the tests required

by the customer.

In fact there are 2 environmental

simulation systems: a climatic chamber compatible with the implementation of a vibrating

system and a controlled ventilation oven; a SmartScope for dimensional

measurements; a dynamometer; a nanovoltmeter; a digital oscilloscope; a melt

flow tester.

The laboratory in Slovakia, developed over

the years in parallel with the growth of the site, ensures the control and

continuous testing of production processes in particular of plastic molding and

the necessary support for the periodic requalification of the product as well

as the activity of problem solving.

It is equipped with basic equipment for the

main mechanical and leak tests and a metrology room with optical measurement

systems and profile projectors for dimensional measurements.