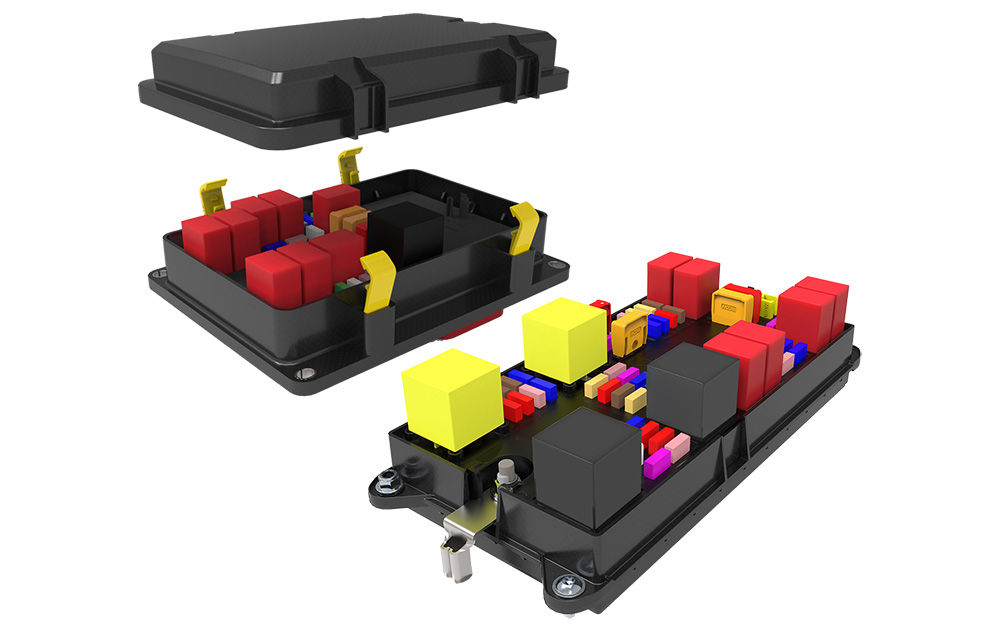

Cube Box

With the Cube Box the customer is given the opportunity to create its own Power Distribution Unit with reduced costs and short time-to-market

In the

ever-evolving automotive industry, the demand for modularity, flexibility, and

customization in electrical systems continues to grow.

Today MTA has introduced a groundbreaking

solution: the Cube Box.

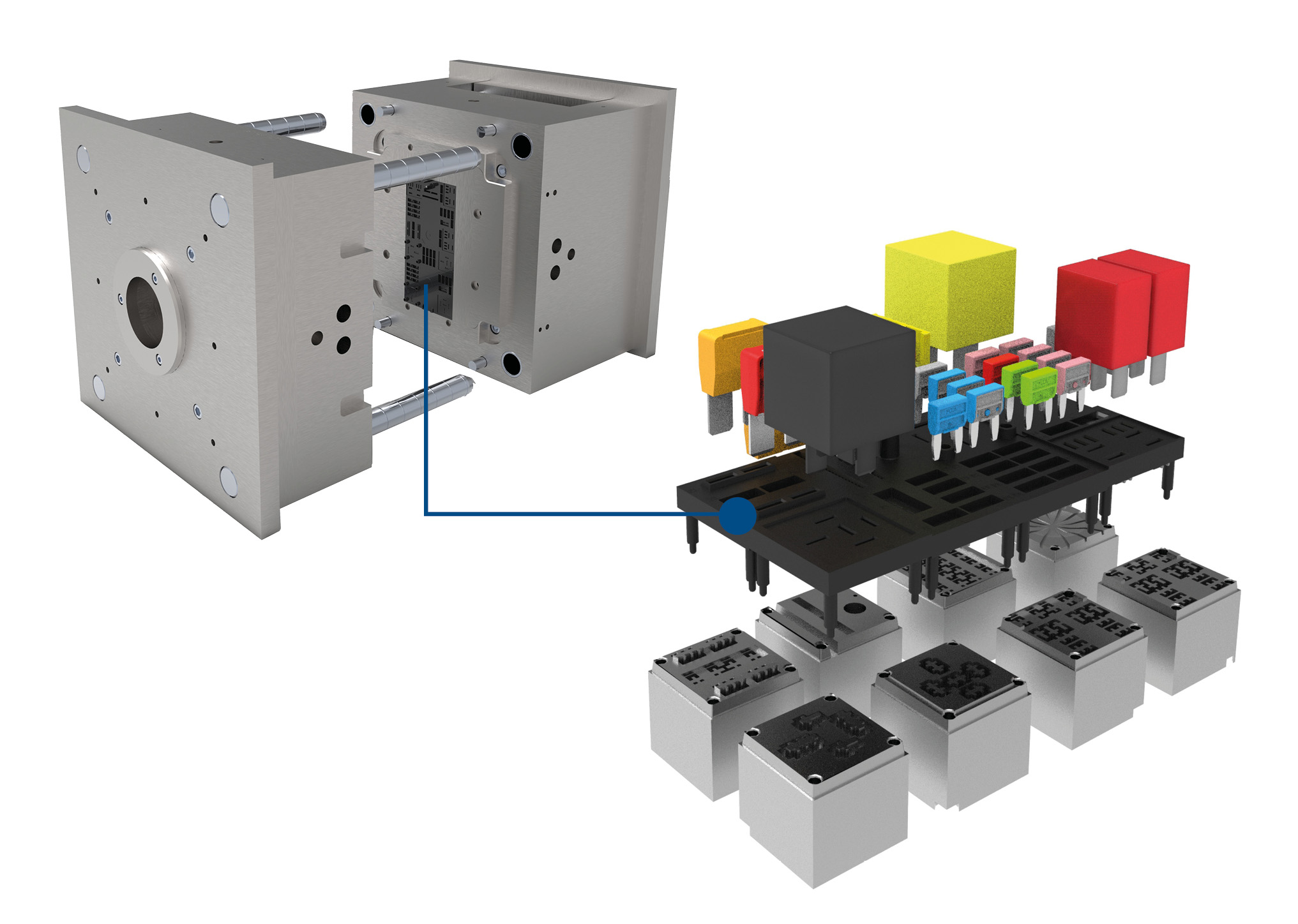

1. Customization starts from the injection mold

At the

heart of the Cube Box concept is a thermoplastic injection mold designed to

accommodate movable inserts. These inserts, each measuring 35x35 mm,

can be freely positioned and oriented within the mold to create a customized

fuse and relay mask. This modular approach allows manufacturers to generate

a virtually infinite number of configurations using a single mold.

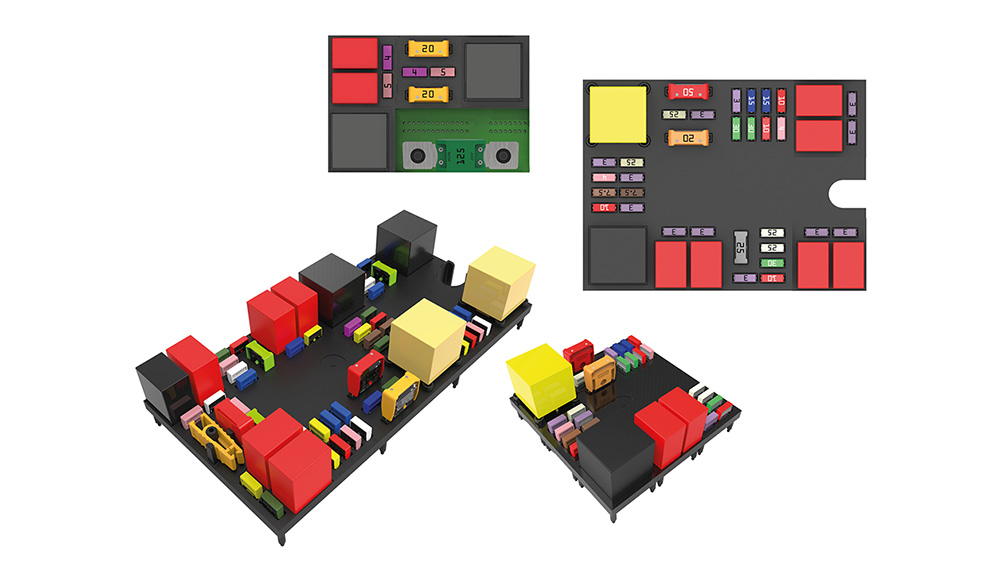

2. The mask can have different sizes and geometries

The masks

can have different sizes and geometries up to a total of 35 modules (7x5)

selected from the range available, offering extensive configurability.

The customers can choose housings for all of our different blade fuse types,

Mini, Uni, Maxi, M8Compact and MaxiCompact; for Mini, Micro and Maxi Relays and

some accessories too. If necessary, it is also possible to provide for the use

of screw-type power fuses, which will be bolted directly on the PCB.

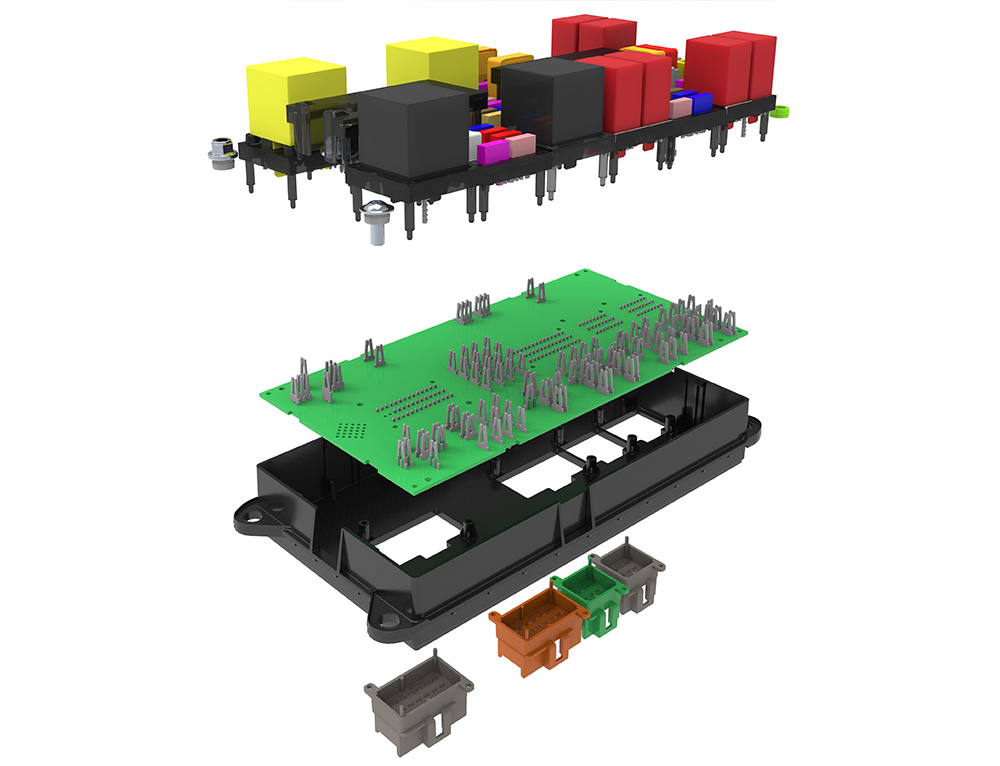

3. The printed circuit board

The PCB itself

is fully customizable to match the specific electrical architecture and pinout

of the target application.

MTA employs press-fit technology for

assembling fork-type contacts and output connector tabs, ensuring reliable and

vibration-resistant connections without the need for soldering. This technique

not only improves production efficiency but also enhances the durability of the

final product.

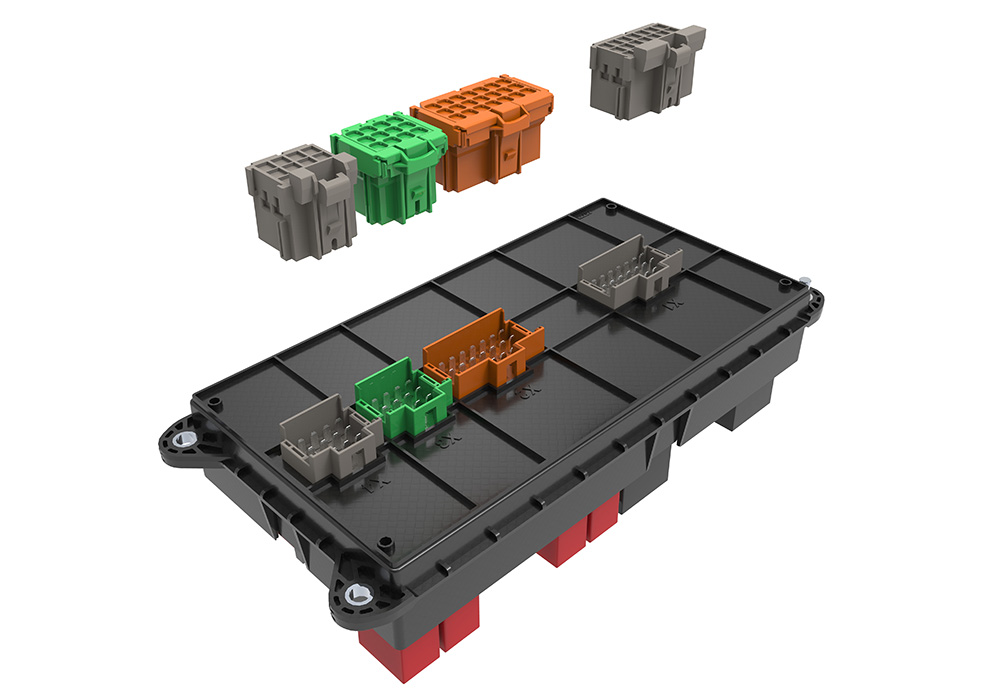

4. Top or bottom side connectors

The

positioning of the connectors is fully customizable. Depending on the

customer’s requirements, connectors can be placed on the top or bottom of

the unit, allowing for optimal cable routing and space utilization.

5. Cabin or Engine Bay

The Cube

Box is available in open and sealed versions, depending on the

environmental requirements of the application. The sealed version is

particularly suited for engine bay installations, where exposure to moisture,

dust, and temperature fluctuations is a concern. The Cube Box meets stringent

protection standards, offering IP67/IP6K9K ratings that ensure

reliable operation even in harsh conditions.

Cost effectiveness and efficiency

Low tooling and engineering costs thanks to standardised processes and housings.

Short time-to-market

The customized PDU can be obtained in very short times thanks to the possibility to compose it from a range of exsisting modules.