Our technological know-how and our experience at your disposal

Read more

MTA acquired Calearo Antenne, a rooted company in the Italian automotive sector

Read more

Easily configurable: the new dashboard for SAME and DEUTZ-FAHR tractors

Read more

The Giotto display for the all-electric Bobcat T7X compact track loader

Read more

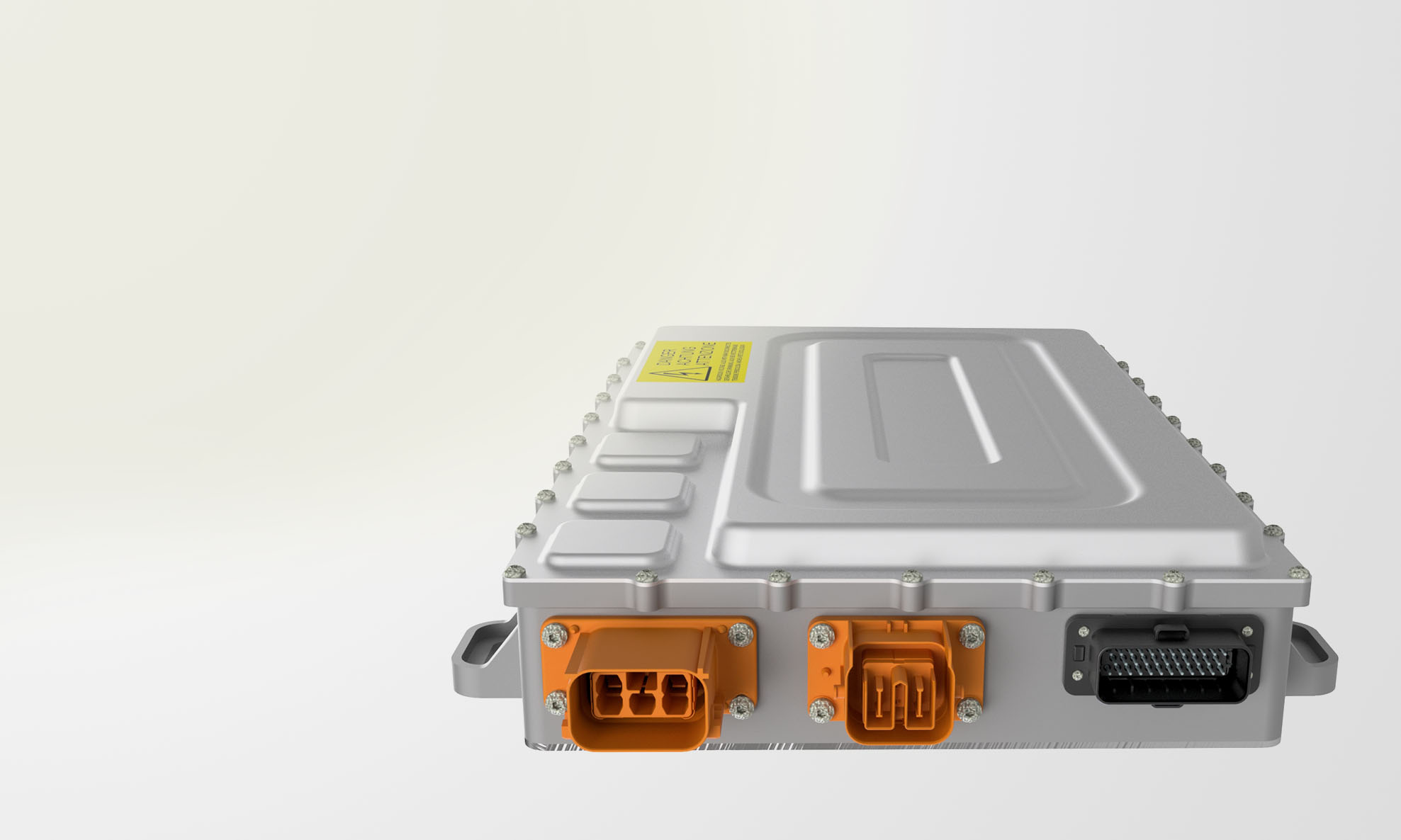

On-board battery chargers for full electric or plug-in hybrid vehicles and for harsh environments

Read more